There are two quite unrelated things to do with wood that are sometimes called a "quality factor", a potential source of confusion.

(1) A measure of internal damping in the wood: it measures how fast the sound of a tap tone dies away. This is often described through a number called the Q factor. The name comes from the world of quartz oscillators for computer clocks etc, where a "high quality" oscillator has very low damping and so a very sharp peak. So high values of Q mean low damping, and a long ring. The formal definition is that 2*pi/Q is the fraction of energy lost in each cycle of vibration. In wood, different types of vibration give different Q factors. Typical values for spruce are 100 or more for long-grain bending, and around 30 for cross-grain bending.

(2) A measure of "wood quality" also sometimes called the "radiation ratio". This has nothing to do with damping, and is determined by the stiffness and density of the wood. It is calculated by posing the question of choosing the wood (or other material) that would make the loudest instrument, on the assumption that you use a fixed outline and arch model, but are prepared to adjust the thickness to keep the tap tones always the same. The answer to that question is to choose the largest possible value of (sound speed)/density, or equivalently of square root(stiffness/(density cubed)). Again, the value will be different along the grain and across the grain: different speeds, although the density is of course the same.

Measuring the speed of sound in violin wood.

Measuring the speed of sound used to require a Lucchi meter, which cost about 3,000 USD. But recently, Don Noon has invented a new way. Very simple. It requires a laptop computer with an external microphone and free Audacity software installed.

How to do it:

Place the wood billet flat on a table that has a towel on it to prevent noise from the table interfering. (For this demo, I used a yardstick, so the frequency will be lower than a 40 cm billet.) Make a small 2 gram hammer out of a suitable nail and wire. Wrap the wire around the nail. I rounded the head of a nail slightly.

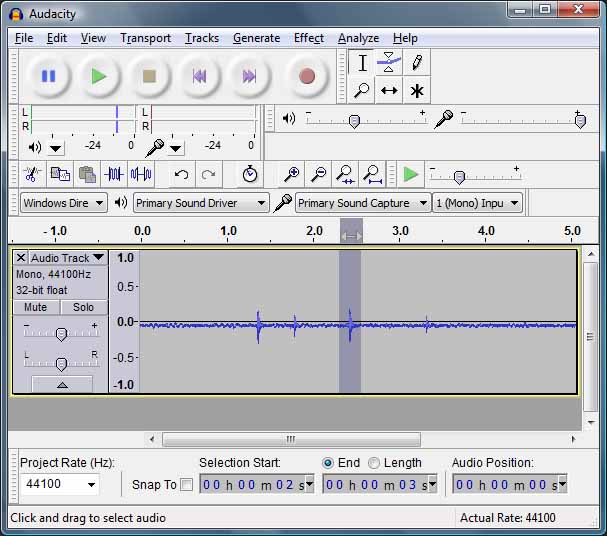

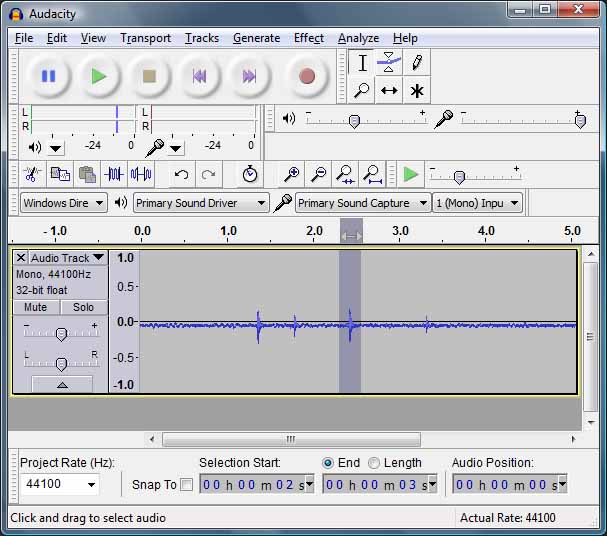

Get the Audacity software running. Place a microphone very close to one end of the wood. Push the "record" button. Tap rapidly the end that is opposite the microphone, 10 to 30 times. Press the "stop" button on Audacity..

In the Audacity window, drag the cursor and elect the recorded sound.

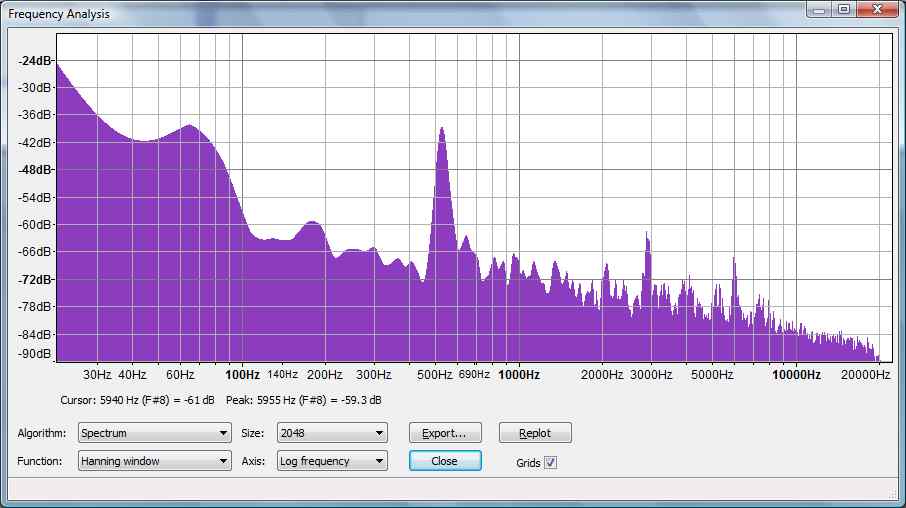

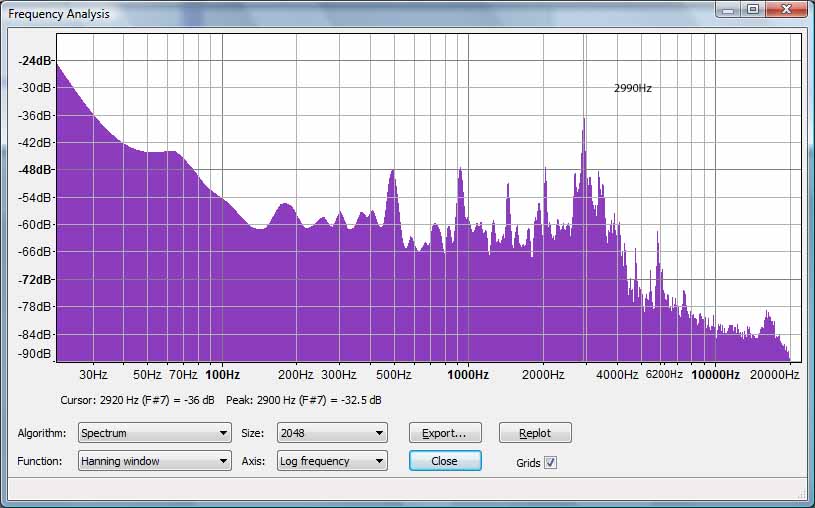

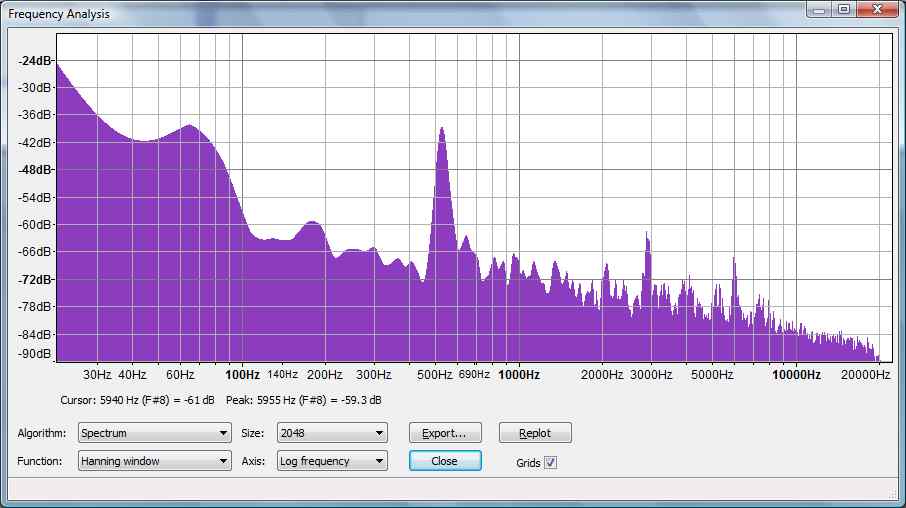

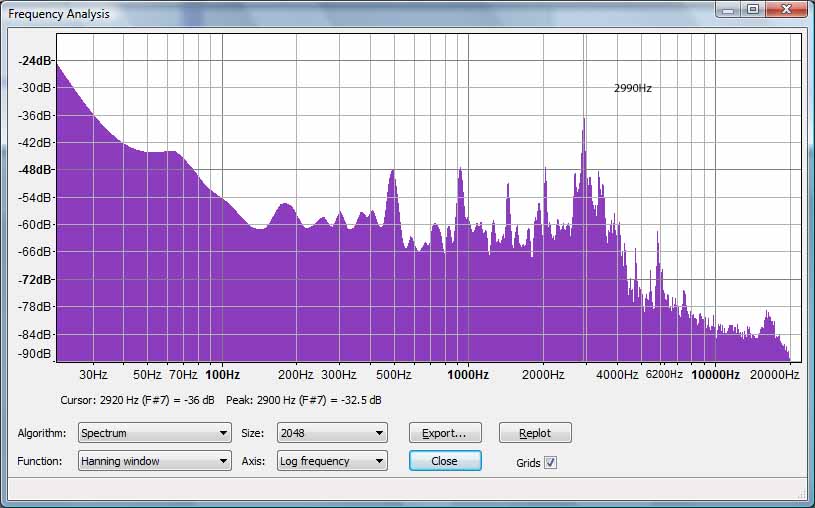

Click "analyze". Click "plot spectrum." Select "log frequency" on the axis button. Select "2048" on the "size" button. Move the cursor to the highest peak, somewhere between 4000 and 7000Hz. Read the peak frequency, F, and record.

Radiation Ratio

Now to calculate the Radiation Ratio, first find the speed of sound C = 2*L*F

As a sample, for my spruce yardstick, L = 0.91 m, and F = 2900 Hz, then C = 2*0.91*2900 = 5278 m/sec. (USA engineers, eat your heart out for not preferring the metric system. Sorry, just couldn't resist.)

So the speed of sound in the wood is C = 5,278 m/sec

The Radiation Ratio = RR = speed of sound/density

If the specific gravity of the wood is 0.45, then the density is 450 Kg/m^3

Therefore RR = speed/density = 5278/450 = 11.7

Rustle Test

I have been having fun using Don Noon's idea that the speed of sound can be found using a computer microphone and Audacity software. Today I found something interesting. Hold the spruce tonewood billet at the xylophone node (0.22*Length from the end). Hold the wood by the node and bring the wood close to the mic. Press "record" and scratch with your fingernail near the mic. Analyze the sound. I found the main peak similar to M5, but also the smaller peak at 5955 Hz, which is the same frequency found in Don Noon's test in which the end is thumped. This is a longitudinal mode. In other words, you can find the speed of sound simply by scratching the wood and knowing the length. At least in high RR spruce, you can.

I called this thread rustle test because I remembered that some people select wood based on how it sounds when scratched. Well, probably using their feeling of the weight of the wood to judge density as well. These two things, longitudinal frequency and density determine Radiation Ratio. Related to how well the wood "rings." Some measure of low damping. IMHO.